Pre-Treatment

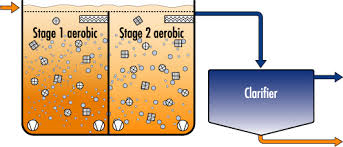

Moving Bed Biofilm Reactor (MBBR)

MBBR is a fixed film biological treatment system that reduces the footprint required to remove organics (BOD) and nutrients from water. This media has a high surface area reducing the treatment volume required to remove the BOD. In addition, the majority of the biological solids are retained in the biological treatment tank minimizing (and eliminating in some cases) the chemistry and separation equipment necessary to remove solids from the treated water. The smaller footprint system provides an economical treatment solution for aquaculture where the MBBR removes organics and nutrients allowing water recycle, industry that needs to remove BOD and nutrients, smaller municipalities, or larger municipalities that need to increase treatment capacity within the same footprint.

Membrane Bio-Reactor (MBR)

Membrane bio-reactors are aerobic biological treatment systems that replace conventional clarifiers with membranes to separate the solids from the treated water. Membrane technology has improved to the point that MBR technology is becoming a preferred technology for municipalities and in industry. MBRs require smaller footprint, use less chemistry, and the membranes effectively remove all suspended solids improving the quality of the effluent. MBR treated water allows water to be recycled sometimes in industry directly without further treatment or with secondary membrane filtration and disinfection.

pH Balancing Systems

Industry often has pH swings from operational process procedures, CIP and sanitation that result in non-compliant issues. AOP’s engineers will get to know your process to design a robust system that is automated and cost effective to reliably maintain compliance 24/7/365.

Building A Lasting Legacy One Drop At a Time.

Building A Lasting Legacy One Drop At a Time.

Dissolved Air Flotation (DAF) Systems

Dissolved air flotation (DAF) systems are proven technology to remove solids and fats oil and grease to pretreat wastewater prior to further treatment or discharge to the municipal wastewater treatment facility. DAF systems can be further integrated to remove phosphorus to meet compliance requirements and reduce BOD and TSS sewer surcharge costs. AOP will design-build the DAF system specific to the industrial requirements to reliably and economically achieve customer objectives while minimizing operator labor hours.

Anaerobic Treatment

Anaerobic treatment often provides the most energy efficient method of treating high concentrated wastes. Anaerobic systems do not require air blowers which at best are 15% energy efficient limited by the amount of oxygen present in the air. Rather anaerobic systems remove organics (BOD) without the use of oxygen converting the carbon organics into biogas consisting primarily of methane and carbon dioxide. Complete mix anaerobic systems can convert 80+ percent of the organics to biogas. These systems are often used in systems that have higher concentrations of solids and/or fats. In the cases, where the wastewater does not have high solids or fats or they are removed with pre-treatment, high rate anaerobic systems are very economical. High rate anaerobic systems can convert up to 90% of the BOD to biogas. The biogas produced by the system has significant energy value and be utilized in a boiler to provide process and facility heating or with a generator to provide electricity.

Containerized Treatment Systems

AOP builds customized containerized treatment systems to meet specific treatment and customer needs. Containerized treatment systems house equipment and system controls in a self-contained 20 or 40 foot steel container. The systems are designed and prebuilt at our facility prior to shipment. Simply set the container on-site connect piping and power and the system is operational. This allows for lower cost and expedited site installation minimizing site impact and provided flexibility to quickly go from install to start-up.

One Project. One Water. One Customer At a Time.

Experts in water treatment

Quality Water Treatment Since 1964